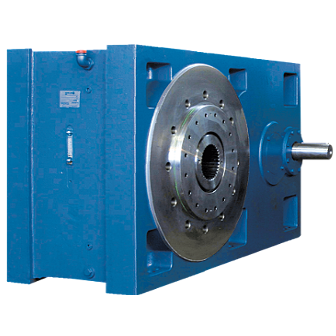

Our gears at the heart of your extruder

Continuous high loads occur here due, in part, to the extreme drive torques that arise here. Malfunctions not only cause costly downtime for the operator, they also result in economic risks due to delays in delivery. As a result, many well-known extrusion system manufacturers do not compromise specifically on these important components and opt for quality gears from Koellmann Gear. Extruder gears from Koellmann Gear have proven themselves in thousands of installations around the world. With its unrivalled functional reliability, the proven cutting-edge technology sets the standard, not only in terms of reliability and a long service life, but in terms of customer satisfaction as well.