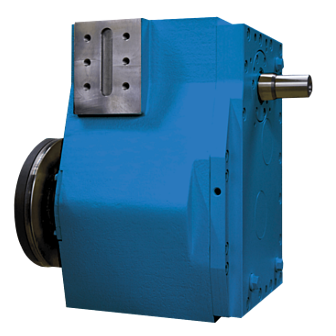

Gear technology for sawing systems

An essential component of sawing systems is the gear technology. Depending on the material being processed, high torques may be required of gears. This is usually accompanied by a requirement that the gear have a low noise level and a long service life, and that it be efficient with the smoothest running capabilities.